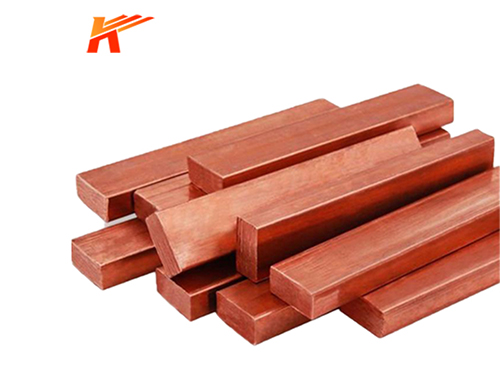

Nickel-stannum copper, a specialized alloy combining nickel, tin, and copper, has gained prominence in various industrial applications due to its unique properties. This article delves into the composition, characteristics, and diverse applications of nickel-stannum copper, highlighting its significance in modern manufacturing processes.

Composition and Alloying Process:

Nickel-stannum copper is a ternary alloy composed of nickel, stannum (tin), and copper. The alloying process involves carefully combining these elements to achieve a material with specific properties tailored to meet the requirements of various industries.

Enhanced Strength and Durability:

The inclusion of nickel and tin in the copper matrix results in a nickel-stannum copper alloy with enhanced strength and durability. This makes it suitable for applications where the alloy needs to withstand mechanical stress, corrosion, or other challenging environmental conditions.

Electrical Conductivity:

Despite its enhanced strength, nickel-stannum copper maintains good electrical conductivity. This property is particularly valuable in industries such as electronics and telecommunications, where materials with both strength and conductivity are essential for optimal performance.

Corrosion Resistance:

Nickel-stannum copper exhibits excellent corrosion resistance, making it well-suited for use in environments prone to chemical exposure or high humidity. This corrosion resistance ensures the longevity of components made from this alloy, particularly in marine and industrial settings.

Solderability and Joining:

The alloy's composition facilitates soldering and joining processes, making it a preferred material for applications where components need to be securely connected. This is particularly relevant in electronic manufacturing, where soldered connections are integral to circuitry.

Electromagnetic Shielding:

Due to its unique combination of materials, nickel-stannum copper is effective in electromagnetic shielding applications. It is utilized in the production of components that protect electronic devices from electromagnetic interference (EMI) or radiofrequency interference (RFI).

Electronic Components and Connectors:

The alloy finds widespread use in the manufacturing of electronic components and connectors. Its combination of strength, electrical conductivity, and corrosion resistance makes it suitable for connectors in telecommunications, computer systems, and various electronic devices.

Automotive Industry Applications:

Nickel-stannum copper is employed in the automotive industry for various applications, including connectors, sensors, and other electronic components. Its durability and resistance to environmental factors make it a reliable choice for use in vehicles.

Sustainability and Recyclability:

As with many copper alloys, nickel-stannum copper is recyclable, contributing to sustainable manufacturing practices. The ability to recycle and reuse the alloy aligns with the increasing emphasis on environmental responsibility in industrial processes.

Ongoing Research and Development:

Ongoing research and development efforts in materials science continue to explore ways to optimize the properties of nickel-stannum copper for emerging technologies and evolving industrial requirements. Innovations in alloy formulations may lead to further enhancements in performance.

Conclusion:

Nickel-stannum copper, with its balanced combination of strength, conductivity, and corrosion resistance, occupies a crucial role in modern manufacturing. From electronic components to automotive applications, this alloy's versatility makes it a valuable material contributing to the advancement of technology and industry. As research progresses, nickel-stannum copper is likely to remain at the forefront of materials engineering, addressing the evolving needs of diverse industrial sectors.