Brass plate processing stands as a cornerstone in the realm of industrial manufacturing, bringing together precision engineering and craftsmanship. This article delves into the intricacies of brass plate processing, exploring its methods, applications, and the vital role it plays in various industries.

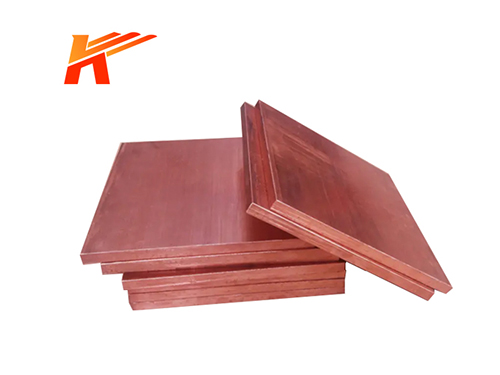

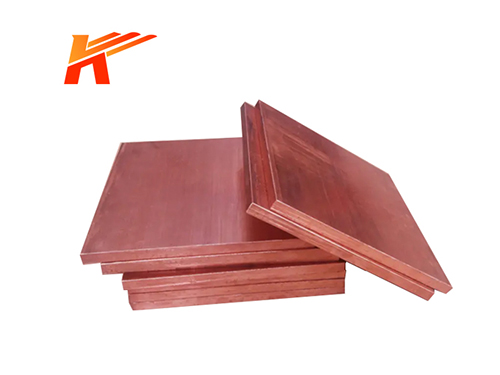

Materials and Composition:

Brass, an alloy of copper and zinc, forms the basis of brass plate processing. The specific composition of brass can be tailored to achieve desired properties, such as corrosion resistance, malleability, and visual aesthetics. This versatility makes brass an ideal material for a wide range of applications.

Precision Machining Techniques:

Brass plate processing involves precision machining techniques to transform raw brass material into finely crafted plates. CNC (Computer Numerical Control) machining, cutting, and milling are commonly employed methods, ensuring accuracy and consistency in the dimensions and surface finish of the brass plates.

Industrial Applications:

Brass plates find applications in diverse industrial sectors. From aerospace components to electrical connectors, the versatility of brass plates makes them indispensable. The corrosion resistance of brass enhances its suitability for applications where exposure to harsh environments is a concern.

Decorative and Architectural Uses:

Brass plates contribute to decorative and architectural elements, adding an aesthetic appeal to both interior and exterior spaces. Whether used in ornate wall panels, door hardware, or furniture accents, the visual allure of brass complements various design styles.

Electronics and Electrical Components:

The conductivity and malleability of brass make it a preferred material for electrical components. Brass plates are utilized in the manufacturing of connectors, terminals, and switchgear, ensuring reliable electrical conductivity and durability in various electronic devices.

Customization and Craftsmanship:

Brass plate processing allows for a high degree of customization. Craftsmen and designers can create intricate patterns, engravings, and textures on brass plates, adding a touch of uniqueness to the final product. This aspect of customization aligns with the demand for personalized and aesthetically pleasing solutions.

Corrosion Resistance:

Brass plates exhibit excellent resistance to corrosion, making them suitable for outdoor applications and harsh environments. This property extends the lifespan of products incorporating brass plates, contributing to sustainability and durability in industrial and architectural settings.

Advancements in Technology:

Ongoing advancements in technology have further refined brass plate processing. Innovations in machining, surface treatments, and coating technologies continue to enhance the performance and aesthetic qualities of brass plates, meeting the evolving needs of various industries.

Environmental Considerations:

Brass, being a recyclable material, aligns with environmentally conscious practices. The recyclability of brass plates supports sustainable manufacturing processes, reducing the environmental impact associated with the production of new materials.

Conclusion:

In conclusion, brass plate processing exemplifies the fusion of precision engineering and craftsmanship, offering versatile solutions across industries. From functional components in electronics to decorative elements in architecture, the applications of brass plates continue to evolve with advancements in technology and changing design preferences. As industries seek materials that balance functionality and aesthetics, brass plate processing remains a key player in shaping the modern industrial landscape.